- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Subaru Europe Unveils the Brand's First All-Electric Compact SUV

- Latest: Lucid, Nuro & Uber Partner on Next-Generation Autonomous Robotaxi Service

- Latest: GM & Redwood Materials to Repurpose EV Batteries for Energy Storage

- Latest: Stellantis Discontinues Hydrogen Fuel Cell Technology Development Program

- Latest: Paving the way for an Electrified Future - L-Charge CEO

Why Silicon Carbide is Essential to Electric Vehicle Efficiency & Charging - Wolfspeed's Lauren Kegley

Lynn Walford

- Jun 12 2023

Silicon Carbide (SiC) technology from Wolfspeed powers electric vehicles (EVs), chargers and high voltage systems to enable energy-efficiency. Lauren Kegley, Product Manager, Wolfspeed, talked to Auto Futures and explained the current and future uses of SiC in automotive and more.

Wolfspeed is an American semiconductor component manufacturer. Wolfspeed is the largest manufacturer of silicon carbide. Its new Mohawk Valley, New York, factory is the first 200-millimetre silicon carbide facility.

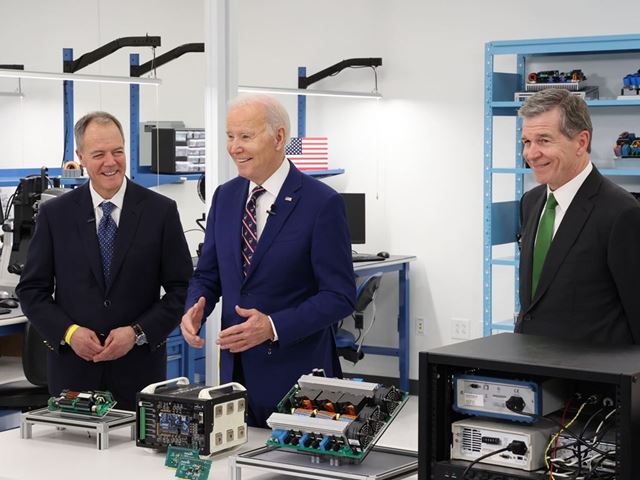

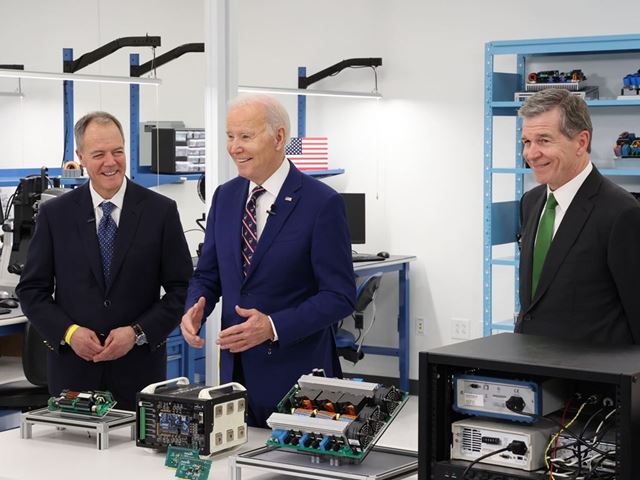

US President, Joe Biden, visited Wolfspeed's Durham, North Carolina, headquarters in late March. It was the first stop of the 'Invest in America' tour.

Why Use Silicon Carbide?

"Silicon Carbide devices deliver high-voltage, high-current, and high-temperature components and help create more energy efficient systems like for an electric car that you want to get the most range out of," says Kegley.

"Because of the lower losses over time as you pull energy out of the battery, silicon carbide provides significant savings at the system level. You can go to higher frequencies and higher densities. Plus, you have improved thermal management capability."

She sums it up this way, "We make solar energy possible for consumers and make range anxiety go away with electric vehicles."

Why is Silicon Carbide Beneficial for EVs And Charging?

Some of the greatest benefits of silicon carbide are in applications with high run rates. For automotive applications, using SiC reduces power losses. SiC makes the biggest impact to pack a lot of power into a really dense space, says Kegley.

Wolfspedd offers many products to support vehicle electrification.

Wolfspeed makes SiC products for offboard chargers for charging stations. Wolfspeed provides SiC technology for onboard chargers that converts the energy to charge the vehicle batteries. Wolfspeed also offers motor traction drives.

"The motor traction drive gives you the power and all the fun of driving an EV," she explains.

"We are starting to see people wanting more and more power out of their electric vehicles. We are seeing a lot more auxiliary power supply demands. For example, the Ford F-150 Lightning is probably the highest power capability right now."

The Ford F-150 Lightning can power a house for up to three days from a fully charged battery.

SiC is also being used for HVAC compressors. In hot climates, HVAC can consume a lot of energy from the batteries. So having highly efficient power electronics is critical, she says.

SiC helps with high voltage systems in vehicles, like the ones from Kia, Audi and Porsche that use 800 Volts.

She noted that the Lucid Air has the highest voltage system at 924 volts. Wolfspeed provides the XM3 silicon carbide power modules for the Lucid Air inverter. It has low switching losses, minimal resistance, and high-power density, contributing to the efficiency and power density of the electric motor.

Comparing Costs of Silicon vs Silicon Carbide

Kegley explained that silicon carbide saves costs in the overall design of systems.

"When you have higher volts, you need higher voltage capable parts. You can do that with standard silicon semiconductors. But you have to do a much more complicated design strategy, called a multi-level design to use the lower voltage. With silicon carbide, you can use a 1200-volt MOSFET and see significant reductions in the complexity of your system as well as the overall efficiency and the power density of your system," says Kegley.

Although the SiC wafers cost more than silicon, they save over the cost of the entire system.

She gave examples of onboard chargers in electric vehicles and EV fast chargers.

"With an onboard charger, for example, you can see about a 15% system-level cost savings when you move from silicon to silicon carbide."

If you look at the EV fast chargers, such as an offboard DC charger, there is about a 10% cost savings at the system level, she explains.

"There are significant improvements in some of the other applications as well. The reason that you can do that is because you can change and improve some of the other components of the system. You can go to higher frequencies, you can go to higher densities, you have improved thermal management capability."

The company is working with strategic partners GM, ZF and BorgWarner. Wolfspeed will supply silicon carbide semiconductors to Jaguar Land Rover's next-generation electric vehicles. Wolfspeed, be supplying silicon carbide devices for future Mercedes-Benz electric vehicle (EV) platforms.

Wolfspeed collaborated with ZINSIGHT Technology to deploy Wolfspeed 1200V Silicon Carbide MOSFETs in its motor controller air compressors in fuel cell vehicle (FCV) engines.

SiC is also reliable. Silicon carbide has the industry's highest level of field hours and reliability, so it is a great material for power conversion.

A great application is the redundant auxiliary power supplies, which can replace the traditional 12-volt battery system or make the 12-volt system just a redundant system, she says.

What is the Future of Wolfspeed SiC Manufacturing And Job Creation?

Kegley was recently in Germany, where Wolfspeed is partnering with ZF and plans to build a Wolfspeed SiC chip factory in Ensdorf, Saarland.

"We're waiting on final approval to move forward with a venture in Saarland, Germany, which will be our first non-US manufacturing facility."

There is another materials factory in the works 'The JP; in Chatham-Siler City, North Carolina. It is named after Wolfspeed's former CTO, John Palmer. The facility is expected to increase materials capacity by ten times.

Wolfspeed is also planning for the future and helping to educate future workers, she says.

"It's not just about capacity, but it's about how Wolfspeed plans to continue to be an American semiconductor leader. Wolfspeed has partnered with North Carolina Agricultural and Technical State University to apply for CHIPS and Science Act funding to support an R&D facility to have a workforce that can support high technology jobs creating exciting opportunities for the engineers and technicians of tomorrow," Kegley reports.

Popular Categories