- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Alpine Alpenglow Hy4 Unveiled With Hydrogen-Powered Internal Combustion Engine

- Latest: Daimler Trucks Presents Autonomous Freightliner eCascadia Technology Demonstrator

- Latest: China's NIO & GAC Announce Partnership on EV Charging & Battery Swapping

- Latest: Automobili Pininfarina Unveils Electric Battista Cinquantacinque

- Latest: Automotive Technology That "Gets Smarter With Every Mile Driven" - Potential CEO

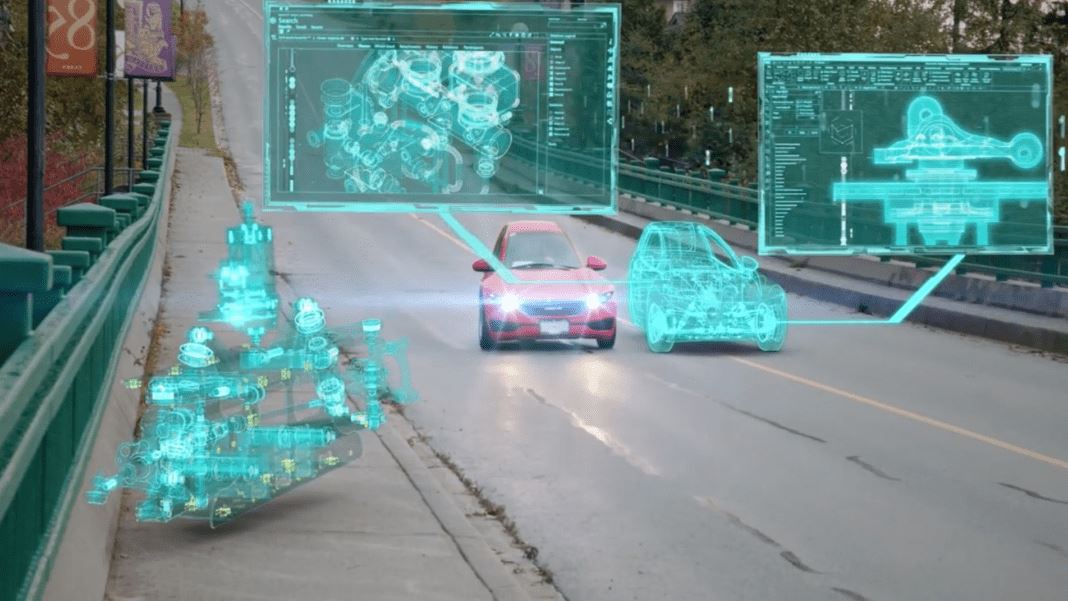

How Digital Twins Can Help Speed Up Innovation In Automotive, Smart Cities, Defence & Manufacturing

Digital twins, simulations of the real world in a digital counterpart, could be a game-changer and a time saver for the future of automotive, electric vehicles, smart cities, defence, and manufacturing. In this special report, Auto Futures talks with leaders in the field to define digital twins, and learn how they can help speed up future innovation.

What Are Digital Twins Good For?

The Digital Twin Consortium (DTC), a group from industry, government, and academia, is working on consistent vocabulary, architecture, security, and interoperability of digital twin technology. DTC has over 250 members and a variety of working groups for different fields.

“We facilitate and create working groups based on interest. Groups are highly collaborative,” says Dan Isaacs, Chief Technology Officer, Digital Twin Consortium.

The consortium defines a digital twin as ‘a virtual representation of real-world entities and processes, synchronised at a specified frequency and fidelity’.” Plus, ‘digital twins use real-time and historical data to represent the past and present and simulate predicted futures’.

“We want to have a continual update of the data to ensure the accuracy of what you have in your virtualisation is in fact up to date. It has to represent accurately what that real-world entity now has. Digital twins use real-time and historical data, to be able to represent the past and present and also simulate with the highest level of confidence. Because of the holistic perspective and the data, you can predict the future,” says Isaacs.

“Digital twins provide you with a crystal ball – based on what’s happened in the past and happening right now to predict and simulate the future,” says DTC steering committee chair, Bill Ruh, reports Isaacs.

Digital Twin Consortium members’ examples include digital twin use in automotive manufacturing, battery management and more. Issacs gives the example of fixing an anomaly found in the manufacturing of cars by robots.

“You need to make sure that you have precision. You know exactly where that robotic arm needs to go and how to do that. So you have a whole simulation. Because there’s a digital twin of this robotic arm doing this process and knowing exactly where to place that drill or rivet, laser soldering or whatever, you can detect anomalies.”

Shop floor data is directly fed back into simulations of the digital twin. They can then figure out whether the anomaly is part of the production system or not, says Isaacs.

Digital twins can help learn how to use batteries better.

“You have basically all the characteristics, the physics and the chemistry of batteries. Real data comes back to you from the battery operation. You can now take that real-world data and say, ‘Does it match my model?’ ‘Is it giving me the accuracy that I need?’ ‘Did I predict my simulation outputs properly?’ I didn’t consider it was going to be in a fast charger. I need to adjust my model for that.

“So now you can refine. Then you can use and apply either machine learning or neural networks to identify ways to optimise battery management in the real world,” explains Isaacs.

Other use cases for digital twins can be simulating sensors for ADAS features, insurance pricing based on a driver’s digital twin and discovering the need for over-the-air updates, says Isaacs.

Digital Twins for UGVs, Drones and Military Use

Digital Twin Consortium member, Duality Robotics, works with many customers. Its customers build robots for warehouse automation, autonomous drones for aerial inspection, defence robots, AI workflows and manufacturing inspections. Duality Robotics makes the photo-realistic Falcon digital twin simulator.

Duality was recently selected to provide real-world virtual environments as part of DARPA’s (Defense Advanced Research Projects Agency) RACER-Sim program. The project is expected to improve automated unmanned ground vehicle (UGV) safety, reliability, adaptability and ability to manoeuvre on off-road landscapes.

“We talk to customers who build robots and show them there is another way to do it. You can use simulation for a large part of your development process. It speeds things up and makes a better product at the end of the day,” says Michael Taylor, Founder and CPO of Duality Robotics.

“We believe there needs to be an open ecosystem with standards for interoperability between all the tools. We believe we need to establish a unified way to think about digital twins across all the various areas of industry that use them. If we can do that as an industry – we can all win,” says Taylor.

Digital Twins and Simulations for Intelligent Traffic Control

Tae-Ho Kim is the co-founder and CTO of Nota and directs NetsPresso, a hardware-aware AI optimisation platform.

He says Nota’s main business is creating Intelligent Transportation Systems. Kim gives insight into why the company uses digital twin tools from NVIDIA to simulate smart transportation.

Nota has three AI products: AI Traffic Cameras, AI Intelligent Traffic Control and AI Crossing.

The goal of AI Traffic Cameras is to collect traffic data using cameras for vehicle detection, tracking and analysis.

Nota AI Intelligent Traffic Control takes the real-time traffic data from the AI Traffic Cameras to the server. The reinforcement learning agent decides the signal timing then its optimal signal policy changes the traffic control.

AI Crossing is the real-time prediction of potential accidents to reduce incidence rates by alerting pedestrians and drivers, says Kim.

“Despite the great achievements of artificial intelligence, we still have very few use cases of AI in our lives. A big challenge of bringing AI to our real life is data collection. Data from the real world is extremely hard to obtain. Generating data sets of rare events or various conditions due to weather or lighting is a big problem,” says Kim.

Car accidents, reverse lane driving and jaywalking are hard cases to find. Plus, data privacy limits data collection.

Simulations or digital twin tools can simulate data that is hard to collect. Interoperability is the pain point of simulation tools. There is a vast variety of simulation tools, each tool serves a different role and use case. Without an ecosystem established, different tools are used, and the outcomes often are not interoperable, says Kim.

Open platform NVIDIA Omniverse 3D simulation real-time true-to-reality simulation and its suite of compatible products offer many solutions for digital twin simulations, says Kim.

NVIDIA Omniverse Connect is an ecosystem that enables various map, environment, sensor, vehicle and traffic model simulators from many sources to be connected.

Another benefit of Omniverse is that Drive Sim and Duplicator are specialised for autonomous driving and transportation. Omniverse Replicator powers Drive Sim for AI tasks. Drive Sim can generate ground truths, weather, LiDAR, radar, road conditions, occluded pedestrians and randomised domains.

Omniverse Create can make videos of diverse lighting, accidents between cars, accidents at intersections as well as accidents between a human and cars, says Kim.

He says Nota is using NVIDIA Omniverse for developing intelligent transportation systems for three reasons. It can respond to various places and environments. It is compatible with existing simulation tools. Omniverse can collect data easily to reduce development time and reduce costs.

“With Omniverse, Drive Sim, Connect and Replicator, we can create the dataset for data collection, connect simulation tools and augment datasets,” says Kim.

Kim invites those interested in the latest developments in AI, digital-twin simulations and smart city solutions to visit the Nota booth at ITS World Congress at the Los Angeles Convention Center, September 18-22.

Future Possibilities For Digital Twins

There are more current and future use cases for digital twins in automotive and mobility.

Siemens reports on its website that ElectraMeccanica engineers designed, simulated, and manufactured its vehicle in two years, using digital twins.

Kevin Mak, Principal Analyst, Automotive Practice, Strategy Analytics, offers automotive use cases and predictions for digital twins for connected vehicles.

Examples of new automotive services from the connected vehicle include a digital twin of the user’s car and that of the model s/he is driving can be compared and enable vehicle repairs before a breakdown occurs. Or that the vehicle sensors can detect a pothole when compared to the road’s digital twin so that local governments can repair the road quickly.

Or that the vehicle sensors detect a hazardous weather condition when compared to the road’s digital twin on a dry sunny day and this can be relayed to other drivers in the vicinity.

Digital twins can be a more cost-effective way of sensing tire tread than installing many sensors in the tire, says Mak.

Digital twins hold great promise, but the concept is new and has not really started yet, remaining as a niche area of interest mostly for engineers, decision-makers and academia.

Also, the amount of data that needs to be stored and analysed can pose problems in its management and communication. The concept requires the involvement of many players and their cooperation. Vehicle sensors can also degrade and may require recalibration, affecting data analysis using digital twins. But with software expertise and edge computing, such challenges could be overcome, advises Mak.

He notes that Strategy Analytics offers reports on digital twins, autonomous vehicles and connected cars.

“We predict that digital twins could increasingly be considered in the design of new cars and the number of services derived from them could also increase,” says Mak.