- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Subaru Europe Unveils the Brand's First All-Electric Compact SUV

- Latest: Lucid, Nuro & Uber Partner on Next-Generation Autonomous Robotaxi Service

- Latest: GM & Redwood Materials to Repurpose EV Batteries for Energy Storage

- Latest: Stellantis Discontinues Hydrogen Fuel Cell Technology Development Program

- Latest: Paving the way for an Electrified Future - L-Charge CEO

From Landfills to EV Battery Factories - How Graphjet Technology is Producing Graphite out of Waste

Adrian Smith

- May 02 2024

Graphite is a form of carbon that is a key ingredient used to make electric vehicle (EV) batteries. Graphjet Technology is the world’s first and only direct agriculture waste-to-graphite technology developer and producer for the electric vehicle (EV) industry.

"It’s actually more important than the lithium itself inside of a lithium-ion battery for EVs. In addition to the accelerating demand for graphite, in my home country, Malaysia, we saw an opportunity for Graphjet to put by-products in the palm oil industry to use – more than 5 million tonnes of palm kernel waste per year," Graphjet Technology’s CEO and Co-Founder, Aiden Lee, tells Auto Futures.

EV battery anodes are almost entirely comprised of graphite, whereas the cathode is where you find the lithium, nickel, cobalt and other materials. In total graphite makes up nearly half of a battery cell and nearly a third of the entire battery.

"It’s the largest material by volume and mass, and there is more than 10 times more graphite than lithium in a battery. It’s crazy how important graphite is to the EV industry, and it’s not talked about nearly enough," says Li.

Launched in 2019, Graphjet is the first company in the world to transform palm kernel shells into battery-grade artificial graphite.

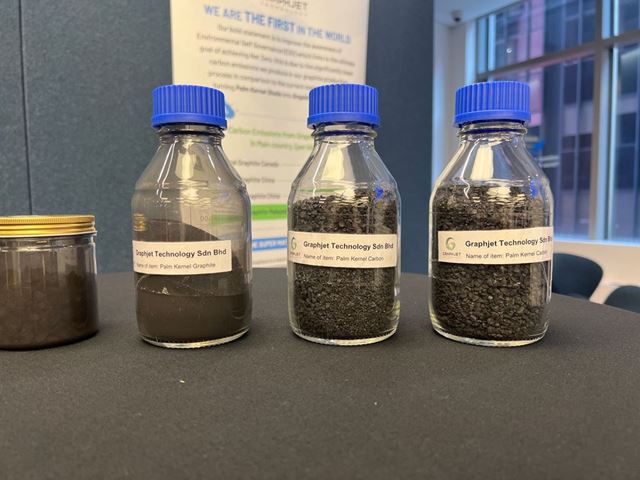

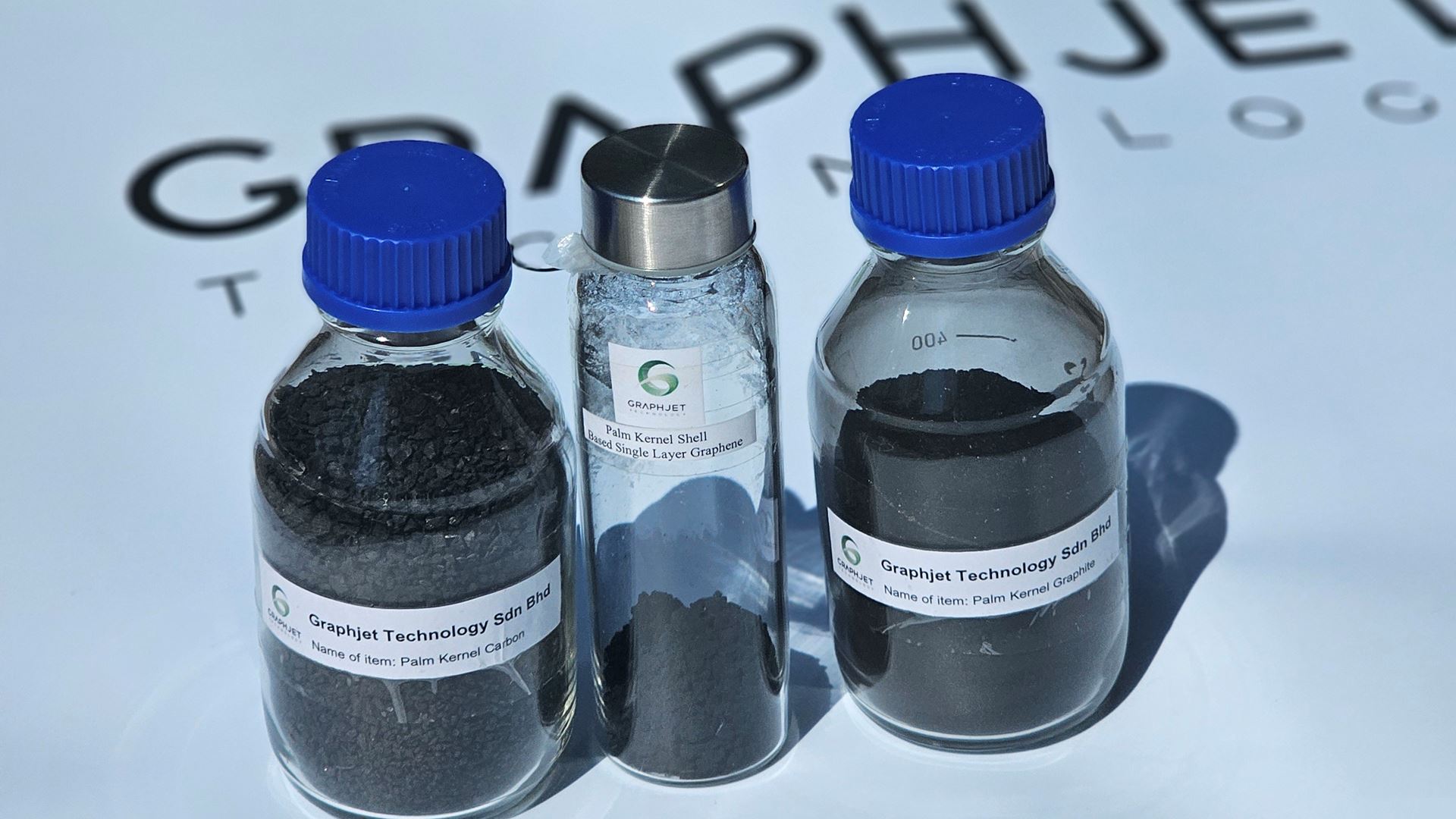

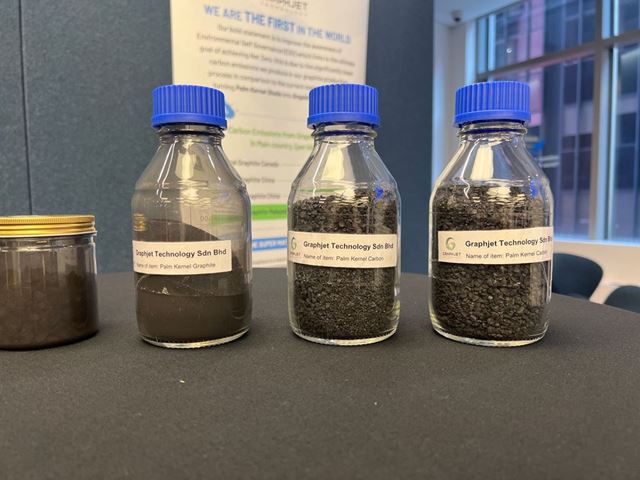

"First, we take palm kernel shell, which historically ends up in landfills, as fertilizer, or a waste burnt to generate electricity for power plants. Once we collect the palm kernel shells from palm oil mills. Then, we use our proprietary manufacturing process to produce hard carbon. Then we take the hard carbon and produce the palm kernel-based graphite."

In addition, it plans to produce graphene from graphite. Graphene is a revolutionary new material known for high conductivity, high strength and ultra-light weight. It is seen as a super material of the future, as it is more than 100 times stronger than steel, and five times lighter than aluminum.

From Malaysia To Nevada

Graphjet took some time to identify the ideal material for its green graphite. It also tried sawdust, coconut shells, rice husk, plastic waste and rubbish in its R&D. It concluded that palm kernel shells - generated in the production of palm seed oil - provided the most significant cost advantages and yield.

"Processes that produce graphite using coal / petroleum coke and mining operations generate high carbon emissions to produce EV batteries. They also have a longer process. Graphjet’s proprietary technology shortens the process and eliminates complexity, which reduces carbon emissions, costs, and improves quality control," explains Lee.

The company has recently announced plans to build a commercial artificial graphite production facility in the US state of Nevada. The facility is expected to be capable of recycling up to 30,000 metric tons of palm kernel material. That allows for the production of up to 10,000 metric tons of battery-grade, artificial graphite per year.

"Nevada is a strategic location for Graphjet as it is located in close proximity to a large quantity of EV battery manufacturers and automakers, which will require a significant amount of graphite for future EV battery production."

It aims to commission and begin production at the Nevada. facility in 2026.

"Once we operationalize our first commercial plant in Malaysia, which is on track to be commissioned in the second quarter of 2024, we will process palm kernel shells into hard carbon, which can be shipped to Nevada. This eliminates a conversion step in our production process, which would enable our future Nevada facility to produce graphite more quickly," he adds.

Creating A Reliable Supply of Graphite

China currently refines more than 90% of the world's graphite into the material that is used in virtually all EV battery anodes. However, it now requires special permits for three grades of graphite to export to the US. This means the US EV market is at risk for not being able to secure a reliable supply.

"Graphjet plans to be the leading source of graphite for the US market, and enable the country to not rely on China for this strategic material. As Graphjet continues to expand and grow larger with support, we are poised to create sustainable, non-polluted and cost-effective supply sources of graphite in North America," says Lee.

Finally we asked him what the future holds for the graphite market.

"Ultimately, Graphjet is tapping into large, high-growth markets for graphite as a $25 billion market is expected by 2027. We expect this growth to continue well into the 2030s," he predicts.

"By 2030, the US government will be expected to have implemented progressively increasing requirements for sourcing critical minerals for battery components, including graphite, outside of China. Graphjet looks forward to cooperating with US policy and regulations to help the US EV market grow" concludes Lee.

Popular Categories