- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Toyota Establishes US Hydrogen Headquarters to Advance Fuel Cell Technology

- Latest: Automobili Pininfarina Develops Bespoke Electric Vehicles Inspired by Batman

- Latest: Gogoro's Global Expansion Plans Boosted by Partnership with Japan's Sumitomo

- Latest: Polestar & StoreDot Charge Polestar 5 Prototype From 10-80% in 10 Minutes

- Latest: How Graphjet Technology is Producing Graphite out of Waste - CEO

#NationalHydrogenDay - The Reality of Hydrogen as the Fuel of Today - Loop Energy's CEO Ben Nyland

Lynn Walford

- Oct 10 2022

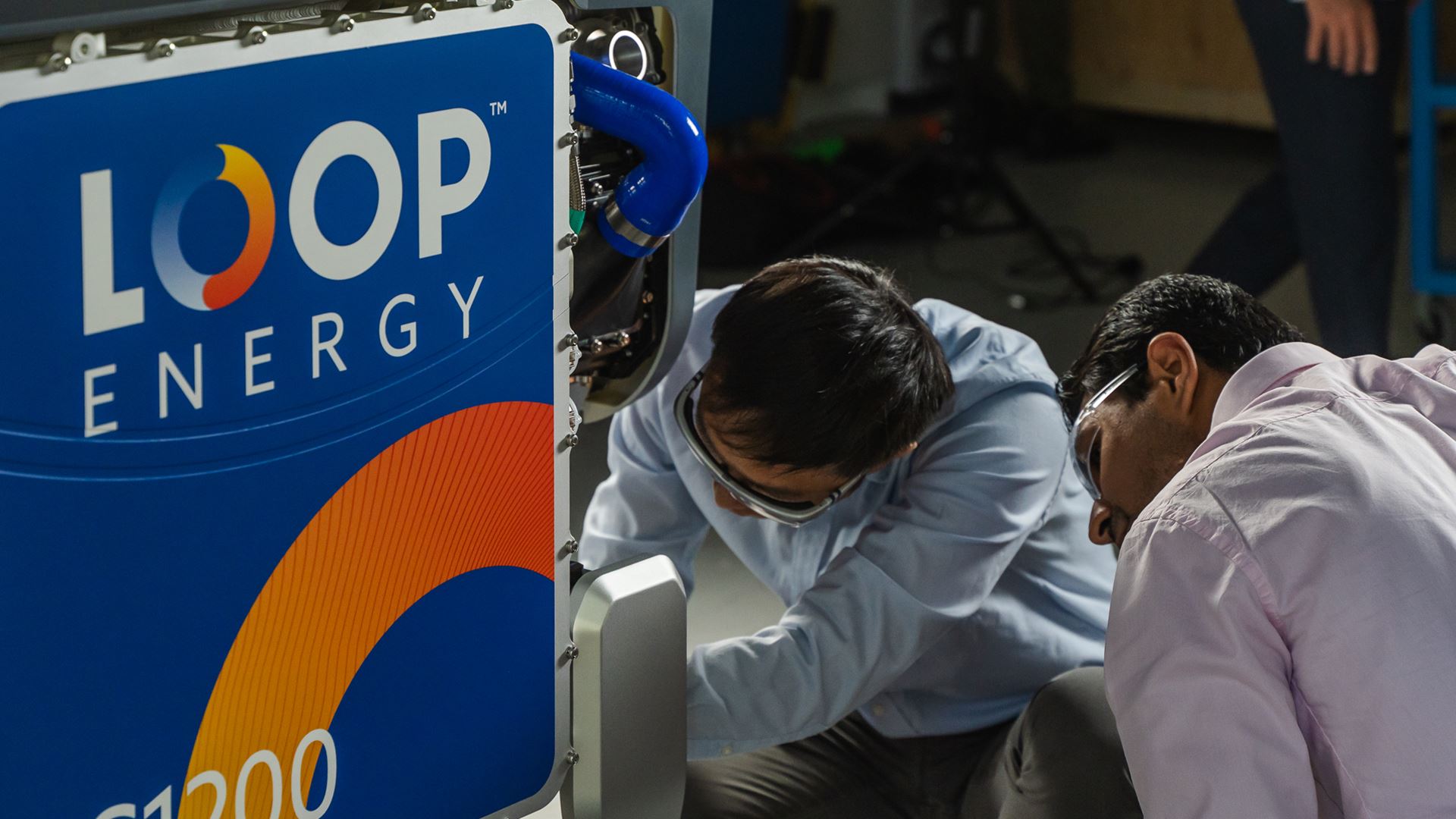

In honour of Hydrogen Day on October 8th, Auto Futures talked to Ben Nyland, CEO of Tier One hydrogen fuel cell systems technology supplier, Loop Energy. Nyland gives an overview of the hydrogen market. He highlights the advantages of Loop Energy's architecture, which is cost-effective for fleets in many regions.

Loop Energy is headquartered in Vancouver, Canada, that is also home to its primary manufacturing facility. Loop has a new manufacturing facility in Shanghai, and will have a service and distribution centre in the UK.

"Hydrogen has been the promising fuel of the future for quite a long time. It is a reality today, which is really exciting. It is finding the right applications in markets around the world. This is really the time for hydrogen. Hydrogen is no longer the fuel of the future--- it is the fuel of today," says Nyland.

Why and How is Hydrogen Better for Buses and Trucks?

Decarbonization is important - but it is not a winner take all situation. There is a reason why both gasoline and diesel vehicles are different engine types. The fuel and economics are different, says Nyland.

"When you look at the market, it's my view, it's not Elon Musk saying batteries are going to take the whole market or Loop saying fuel cells are going to take the whole market. Batteries work very well for cars but are too heavy for buses and trucks," explains Nyland.

"When you try to power heavier vehicles completely with batteries - you have a curb weight issue that reduces your cargo capacity," he adds.

Battery weight directly impacts economics because BEV trucks carry less cargo. Fleet operators are then forced into situations where they have to buy more vehicles and hire more drivers to move the same amount of cargo. The costs go up and it just doesn't work, says Nyland.

"If you put a fuel cell in a heavy vehicle, it gets rid of that weight issue. It brings the cargo capacity back up and increases the range."

For any commercial vehicle that needs to operate more than one shift, recharging the batteries daily is not an option. Whereas with a fuel cell, the hydrogen tank can be refilled in about 10 minutes or maybe 20 minutes for the bigger vehicles. The vehicle has full capacity, says Nyland.

"Tesla's Class 8 truck is now supposed to spread the batteries into the trailer. That doesn't deal with the curb weight issue, which is limited."

How is Loop Energy Lowering Operating Costs?

"Our focus in our products is initially to get that operating cost lower. We have gotten the service and maintenance costs low. The other biggest contributor to operating is fuel costs. The S1200 achieved new levels of efficiency that allow it to compete directly with diesel on a cost-of-fuel basis," says Nyland.

At IAA Transportation, Loop introduced the S1200, with an efficiency gain of 20% for electricity generation. Loop research compared using the S1200 to diesel, using the average price of diesel and hydrogen in Europe.

"Loop's efficiency enables hydrogen to be competitive with diesel fuel costs now."

The plug-n-play 120 kW S1200 fuel cell is a fully-integrated system with flexible packaging and moveable components.

Nyland says that Loop has achieved better efficiency than its competitors because the company has been working on fuel cells since 2000. Founder David Leger and a team of engineers invented eFlow, the company's patented bipolar plate fuel cell technology.

"We are working with vehicle manufacturers who have concrete credible plans to scale the production of their hydrogen vehicles. And we are establishing ourselves as the go-to supplier of the hydrogen modules that will go into those vehicles."

What Companies Use Loop Energy's Tech?

Curb weight can be a problem in older cities with smaller roads. The hydrogen itself is extraordinarily light, reports Nyland.

"We have a customer in Europe, Mobility Innovation, that manufactures an eight-metre bus. It is a small bus designed for European cities which have very tight streets. They designed a bus that uses our fuel cell system and 10 kilograms of hydrogen. It can go up to 400 kilometres. That's 240 miles on 10 kilograms of hydrogen."

Skywell and Mobility Innovation are in a scale-up phase using Loop Energy technology. Companies piloting the Loop fuel cell system for buses include NGVI, ARCC and Mottem. Morello is piloting hydrogen fuel cell warehouse transportation. Loop announced its systems are in full-production in Tevva Motors' medium-duty truck.

The company recently announced partnerships with Opex/Hevolucion, a systems integrator of batteries and hydrogen fuel cells in Columbia, and Avia Ingeniería, an electric powertrain provider and systems integrator in Spain. The partners will use Loop Energy's S300 (30 kW) fuel cells as range extenders.

Loop systems can also be used for stationary energy storage. Ecubes, Emfeld and Hylife Innovations are piloting stationary power systems.

Refuelling hydrogen fuel cell vehicles is getting easier. "There are multiple companies delivering hydrogen. Multiple companies can set up a hydrogen fueling stations for return-to-base fleets."

He concludes: "I think that the commercial vehicle industry has hit an inflexion point. There is a broad consensus that hydrogen has to be a solution for the industry to decarbonize. We are now seeing major corporations commit significant capital towards that transition. It is simply a matter of how long it's going to take. Not whether or not it's going to happen."

Popular Categories