- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Honda to Invest $11 Billion in EV Supply System & Capability in Canada

- Latest: CATL Unveils Shenxing PLUS, Enabling 1,000-km Range and Superfast Charging

- Latest: Mercedes-Benz Announces In-car Gaming Cooperation With Tencent & Electronic Arts

- Latest: LG Chem & Factorial Announce Plans to Develop Solid-State Batteries

- Latest: The Rise of the Humanoid Robots (and how OEMS can Benefit) - Apptronik's CCO

The US Startup Intent on Making Lithium-Ion Battery Fires a Thing of the Past - Nuvola Technology CEO Janet Hur

Adrian Smith

- Jul 27 2023

Potentially fatal electric vehicle (EV) and e-bike battery fires are making headlines almost weekly on both sides of the Atlantic. LA-based startup Nuvola Technologies has developed a technology that eliminates the primary cause of lithium-ion battery fires. It can also help battery manufacturers reduce scrap and therefore save million of dollars in costs.

The company was founded in 2015 by two University of California researchers – Dr. Janet Hur and Dr. Leland Smith.

"While the number may be low, more than zero is too many," says Dr. Hur, Nuvola Technology's CEO, about lithium-ion battery fires.

"The primary cause of Lithium (and other) battery fires is when the sheet separator material becomes folded, torn, ripped, or stressed. If the anode and cathode (the electrodes) come in contact (from the sheet separator assembly defect), a thermal runaway and fire can result. This problem can show up days, weeks, months, or even years after the battery is assembled," explains Dr, Hur.

The 50-year-old sheet separator technology is prone to manufacturing assembly errors and failure. During the battery assembly process, a single sheet separator can become damaged, creating an undetectable wrinkle, misalignment, misfolding, or even a tiny tear allowing the electrodes to come in contact.

"Many, but not all, defects are detected at the battery manufacturing factory – but even in a well-run, mature design assembly line, defective batteries make it out of the factory into products."

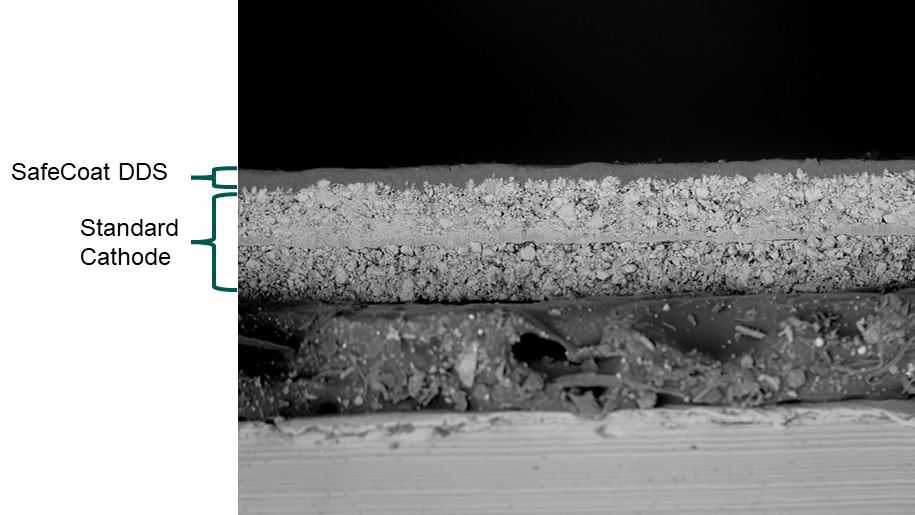

Nuvola's SafeCoat DDS is a special polymer coating that replaces the traditional and troublesome sheet separator. It is a spray-on coating that fully covers the anode and/or cathode, making sure that they never come into contact and cause a fire.

"You see many more fires with e-bikes and e-scooters (usually made with inexpensive batteries manufactured without sophisticated quality control. Tragically several of the fires this year have resulted in multiple deaths (the device catching on fire while stored in a home or apartment building). The damaged separator product issue impacts all devices that use high energy Lithium (and other chemistry) batteries – EVs, energy storage systems, e-bikes, and even cell phones."

She warns: "How much risk is the industry willing to take with a sheet separator assembly error in batteries used in an e-aircraft?"

Modifying The Battery Manufacturing Process

Other than fires, the largest impact of the sheet separator assembly issue is the huge amount of scrap it causes in the battery manufacturing process. This error can cost manfacturers millions of dollars a year.

"The error cannot be detected until the battery is fully assembled and tested at the end of the manufacturing line. By this time, the battery company has invested all the time and raw materials (and cost) in the battery. This 'late-in-the-game' error detection issue is causing a considerable battery scrap issue," says Dr. Hur.

"Any issues with the SafeCoat process can be inspected and corrected very early in the battery manufacturing assembly process – impacting only a single electrode. Any problem is found early, and the product can be reworked and repaired before being sent on its way down the line as a perfect battery."CEO Nuvola Technology

Nuvola's breakthrough technology has received accolades from the industry.

In a press release, James Hodgson, Research Director, Automotive at ABI Research, states: "Improving battery safety is one of the highest priorities for the EV market, with large, energy dense batteries representing a significant threat to public safety in the event of a fire. Nuvola Technology’s approach of separator coating offers the opportunity to improve both safety and production yield by modifying one step of the manufacturing process.”

In 2022, Nuvola was selected as one of ten winners in LG Energy Solution's annual Battery Challenge, competing with over 100 companies. The LG Battery Challenge competition is designed to accelerate the adoption of new battery technologies and business models.

SafeCoat is also battery chemistry independent and designed to work with emerging anode and cathode material technologies.

"The SafeCoat product is under evaluation by several EV battery manufacturers. We hope to see batteries using the technology as soon as 2025. With EV batteries built using the SafeCoat DDS product, battery fires will hopefully be safer and a thing of the past," concludes Dr. Hur.

Popular Categories