- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Opel Unveils Next Generation All-Electric & Hybrid Grandland SUV

- Latest: B–ON & Chery Commercial Vehicle to Develop Electric Commercial Vehicles

- Latest: Valeo Merges Powertrain & Thermal Activities to Create Valeo Power Unit

- Latest: China's Zeekr Presents Deluxe Version of its MPV Named the 009 Grand

- Latest: The US Startup Rolling out Urban Curbside EV Charging - Voltpost's CEO

#EarthDay - Vegan Leather & Plant-Based Topcoat: Changing the Supply Chain - Vicki von Holzhausen

Lynn Walford

- Apr 20 2023

In honour of Earth Day, Auto Futures is profiling people and companies innovating with sustainable products for automotive and mobility. von Holzhausen is a Californian company dedicated to creating carbon-negative materials that replace leather and plastic. Founder, Vicki von Holzhausen, discusses why she formed the company and described its new sustainable materials and future plans.

A graduate of ArtCenter College of Design, von Holzhausen was raised in Pasadena, California, near the campus.

"I decided I was going to be a designer at 10 or 11 years old. I started going to ArtCenter at about 11 years old," she says.

She began her career as an automotive designer, designing luxury models for Audi and Mercedes Benz. She launched the von Holzhausen company in 2015.

"I come from the automotive industry. The company merges a lot of my interests and the things that I had been working towards my whole life," she says.

"I'm a vegan. I care a lot about sustainability and animal rights. I am also a designer, so I thought about how my personal life and values could affect my design work. Ultimately, that was one of the reasons I moved into creating my own business - rather than staying in the automotive space," she adds.

"I wanted to use whatever abilities I had to help solve the issue of global warming. The company started making alternative materials and then moved quickly to alternative materials for accessories because I did not see any reason why we had to use leather anymore for fashion accessories or anything else."

Development of von Holzhausen Materials

She pointed out that typical pleather, faux or vegan leather materials, is 100% petroleum-based. The industry is destructive to the environment and contributes plastic pollution.

"We started to develop our first material - Technik-Leather was the first one. The case collection for Apple, sold worldwide, is made out of Technik-Leather," says von Holzhausen.

"Technik-Leather evolved over time Technik-Leather has a plant-based topcoat now. It started off as a recycled plastic water bottle material. Now it has become a plant-based material."

"After Technik-Leather, we launched Banbū Leather, an 83% plant-based material," she notes.

Banbū Leather has been very much sought after by the automotive industry because Banbū Leather has plant-based content. But not only that, it is a performance-oriented material, she says.

Banbū Leather is qualified for automotive application. It passed strict industry specifications that all the OEMs have. It is also scalable. It is not made in batches in trays. It is made in yardage - linear yards, she adds.

"We are working with a lot of OEMs on Banbū Leather. They are super enthusiastic about getting it into production."

It is a state-of-the-art innovation that meets or exceeds the performance requirements of leather and is also biodegradable.

"Banbū Leather is really cool because if you throw it into a landfill or a zero oxygen environment, it will biodegrade within 250 days, leaving zero microplastics."

Where Can You See Banbū Leather?

There is a Tesla Model S upholstered with Banbū Leather - from aftermarket company Unplugged Performance - on display at the Petersen Museum in Los Angeles.

"It is really exciting because the product is exciting. The museum is an easy and quick way to show how the material looks and feels. People can go and touch it and sit in it," says von Holzhausen.

What's So Bad About Leather And PVC?

Livestock production contributes to climate change, biodiversity loss, environmental degradation, air and water pollution, excessive waste and public health risks. Leather production uses water, toxic chemicals and petroleum products. Many people may think leather is natural however, to make it durable for automotive use, it is coated with polyurethane, a petroleum-based product.

She notes that leather is the worst of all worlds: "You have an animal product and you have plastic altogether in a composite material called leather for your car seat."

For automotive upholstery, PVC is also used. PVC is an extremely toxic, low-grade plastic material. 100% petroleum-based material, she noted.

How Durable Are von Holzhausen Leathers?

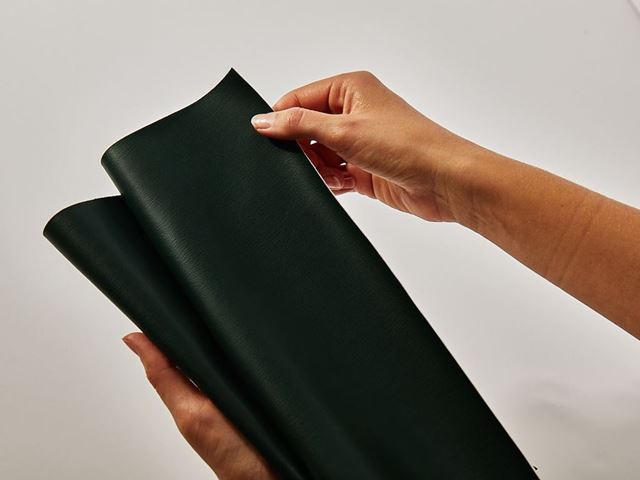

The company's alternative leathers: Struktur, Technik-Leather and Banbū Leather - shown on its website - are at scale and are made in rolls. von Holzhausen reports that hundreds of thousands of Apple Technik-Leather cases have been sold.

"The Apple team has told us that their customers can not tell the difference between our material and leather and that it is really durable. It is amazing how much wear and tear that material has gotten and really great reviews," she says.

von Holzhausen sells Banbū and Technik-Leather accessories and handbags on its website.

"Banbū Leather is an automotive quality material. If think about how many times you go inside and outside of a car for ten years---- your handbag will never go through that type of torture. The handbags have tremendous longevity."

To illustrate the effects of smell on emotions - von Holzhausen produced the Banbū Leather candle.

"People are connected to leather because they love the smell of leather. Like- 'I've got this chair and I love the smell of it.' So we decided to talk about the emotional side of our material and gave it a smell. That is why we launched the Banbū Leather candle The idea is about connecting all your senses to these new materials," she says.

"If a company wanted to engineer our material with a special scent, we can definitely include that," says von Holzhausen, who notes that materials can be made in many textures and any colour.

Liquidplant - Stretching Innovation

The latest miraculous material from von Holzhausen is Liquidplant.

"Liquidplant is the innovation that multiple industries have been looking for. It solves the problem of plastic topcoats," says von Holzhausen.

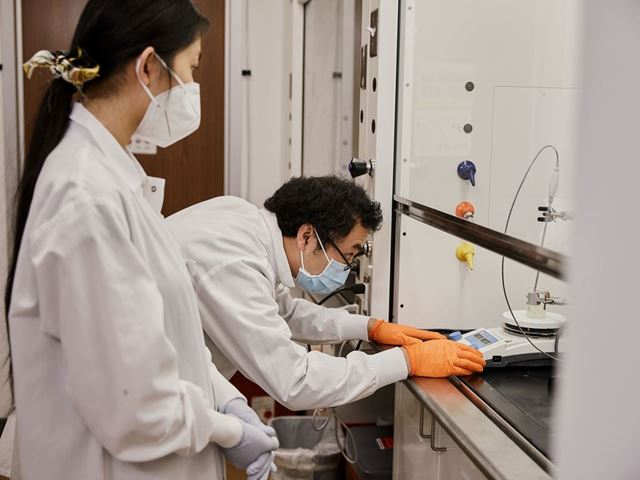

Liquidplant is 100% plant-based. It uses things like sugars and oils and crosslinks them in a robust way through proprietary technology and processes. It processes them in a way that makes it durable. The molecular level has been altered, says von Holzhausen.

A video on the von Holzhausen website shows Liquidplant as clear and stretchy. The material however has great potential for haptic qualities.

"We can make a clear topcoat but what we do with it is make a full material out of it. This material can look like leather. It could look like something totally different than leather depending on the grain and colour that you put on it. This material is made out of agricultural waste on the backing. Then on the topcoat, is made out of Liquidplant."

She showed a sample that looked like leather but was stretchy like Lycra or Spandex.

"It is malleable and drapey. To me, it feels like lambskin or like glove leather, something really luxurious. But that can also be changed by how we treat the topcoat. We have haptic topcoat treatments, which change the feel of it."

"We are making our material pliable to meet the performance criteria. We have a set of testing methods that we use to ensure that the material is usable. We are going after those targets, whether it be this much elongation or these many times scratch it. There is a test called the Martindale test which scratches the material 100,000 times. We are going after a set list of criteria for the development of Liquidplant."

She calls Liquidplant a full-circle solution. Products made out of Liquidplant are performance oriented and have longevity. At the end of the lifecycle, when thrown away - the ingredients will become nutrients in the soil because they are made out of sugar, plants and seeds, she says.

The Future Of von Holzhausen Materials

von Holzhausen announced a partnership last year with Nanollose, which makes fibres from bacterial cellulose.

"We are working in collaboration with Nanoloue to make a composite material. The composite is our top coat technology with their bacterial cellulose fibres," says von Holzhausen, "It is a treeless fibre and ours is plastic and petroleum-free top coat creating a future-minded material. There's nothing like that that exists," says von Holzhausen.

Liquidplant is part of a pilot program. The company is choosing partners that align with von Holzhausen's sustainability vision and have interesting problems to solve.

"The goal is to commercialize Liquidplant at the end of the pilot program. It is about talking to as many companies as possible and working with them and changing the supply chain," reports von Holzhausen.

Popular Categories